Okamoto Machine Tool Europe, the specialist manufacture of precision grinding systems, is exhibiting at EMO 2019 and introducing a range of new machines and programme upgrades.

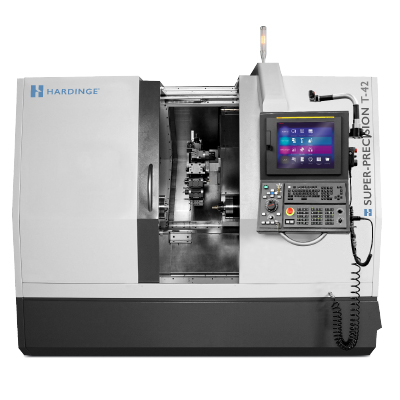

Okamoto is exclusively represented in the UK and Northern Ireland by Rugby based Jones & Shipman Hardinge Ltd and its machines complement those manufactured by Hardinge grinding sector companies Kellenberger, Hauser, Tschudin, Usach and Voumard.

Being exhibited for the first time is the new ACC-63SA1 surface grinder. This model replaces the popular Okamoto SA Series and is available in 6 table sizes, 500 x 200mm up to 1000 x 500.

Machines in the ACC-SA1 series feature an easy to use touch screen colour graphic control for implementing advanced surface grinding operations with the best productivity. It enables a fully automatic grinding operation for standard surface grinding or shift plunge surface grinding with automatic compensated dressing from the table for even higher autonomy and productivity.

The ACC-SA1 machines have a robust rigid cast iron construction with high static and dynamic stiffness and excellent damping characteristics. The hydraulically driven table features double V slideways with minimal overhang and non-contact switches for table reversal. All slideways have automatic lubrication.

Okamoto will also introduce a new, improved GX range which is the next generation of its popular DX surface and profile grinders. The upgraded machines feature a new colour scheme and improved table enclosure.

The six machines in the range feature the well proven and reliable Okamoto control which provides a fully automatic grinding operation. The grinding method is selected via switches on the main panel and feed-rates and feed change points can be set and adjusted at any time by a potentiometer. Down-feed offers a choice of coarse and fine feed and the control has been improved to include table park and wheel head retract features at the cycle finish.

The UPZ-Li series with its ultra-precision linear motor has been expanded with the UPZ-63Li model now featuring a 600 x 300 capacity table and a rotary table. The Okamoto UPZ-63Li is an ultra-precision CNC profile grinder with fast oscillation linear motor table drive. It has a column moving construction and rigid structure for optimum precision.

Okamoto’s CAiQ surface and profile grinding machine has also been upgraded with the addition of Fanuc controls. These high specification machines are ideal for toolroom applications or small part production work. The upgrade to Fanuc provides improved operator access and higher clarity and resolution graphics via a large touch screen control, without any cost increase on the basic machine price.

Finally, the UGM360NC is a precision cylindrical grinding machine with a B axis. Featuring a 10-step grinding programme the wheel and work spindles are driven by Fanuc servo motors. The swivel B axis has a direct drive servo motor.

In total six machines will be operational on the stand and the Okamoto Europe Sales Manager Mike Jollands and his team will be present to discuss machines and applications. Mike Duignan, Managing Director of Jones and Shipman Hardinge, Okamoto’s exclusive UK distributor will also be in support at EMO.